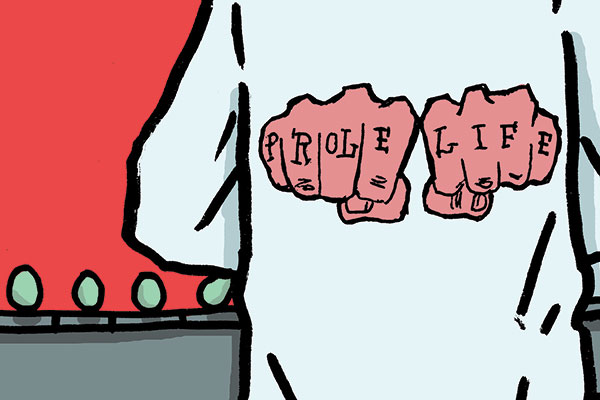

Prole Life

“It’ll only be a few months,” I assured my Mum.

“I’ll stay in Dunedin – there’s bound to be more jobs than in Wairarapa.”

Having passed my final papers, and with nothing to do until my departure for a TESOL gig in mid-September, the winter stretched out ahead of me.

As I scanned TradeMe Jobs and Otago Daily Times classifieds, however, my heart sank. Any illusions of holding a cushy (or even bearable) office job were discarded alongside the rejection emails that trickled depressingly back into my inbox. I realised the humbling truth: unable to commit to a job for more than a few months, my painstakingly accumulated skills and education had all the market value of a dropped pie. I was, in effect, a prole, a pleb, or one of those countless other names my classmates had used to casually insult the people who did the jobs we were all too good for.

For the first time, I made a rent payment that was not covered by StudyLink’s wonderful weekly transfers. Seeing how this decimated my bank account, I reluctantly shuffled into the WINZ offices on St. Andrew Street. The depressing, open-plan office brimmed with “work brokers” and copies of the in-house magazine, Rise. Its cheery pages told stories of wise case-managers successfully sending teen mums out of the nursery and into call centres. When I learnt of the three-week stand down period for a benefit, I fled. WINZ’s vague promise of jam tomorrow was not worth the enormous stigma of becoming a beneficiary.

The wolf was now truly at my door. Money making-schemes rushed feverishly through my mind. Cannabis would require too great a capital investment, not to mention too much waiting until maturity. Psychology experiments were insufficiently numerous to keep me going. Finally I accepted my fate, and headed to one of Dunedin’s temporary labour agencies, Select Recruitment. Their promises of hard work, long hours and poor working conditions were strangely comforting.

Following the recruiter’s advice, I headed out to buy steel-capped boots. As much as I would have loved to buy organic vegan iguana-skin boots made by artisanally-trained FARC rebels raising money for breast cancer survivors, my meagre funds compelled me to head to the Warehouse, where a lonely man sat on the shoe-trying bench.

Seeing the boots, he asked me where I would be working. “Maybe the Gregg’s factory,” I replied, recalling the recruiter’s list of employers willing to accept whatever unskilled hands the agency could provide them. “Then tell Rob Finch, if you see him, that Chris says hi.” I told him I would, and then hurried to aisle 14 where a special announcement over the shop’s loudspeakers informed me that there would be a free giveaway. There, in the style of a religious revivalist, a travelling saleswoman gave a sermon to a hushed crowd about how her ever-sharp knife would save us from the trials of filleting fish, slicing tomatoes and cutting hammers. A squat Maori lady and a tall man with a limp were one of many to receive this serrated sacrament. I left with a complementary potato peeler, not knowing that the pair would be my future workmates.

My first assignment was indeed the Gregg’s factory. After donning a hairnet, dustcoat and gloves, and inserting earplugs that rendered most people incomprehensible, I was shown how to use the heat-sealing machine. At the start of our little production line, two tempo workers scooped coffee into plastic packets of Gregg’s “Red Ribbon Roast.” A full time worker weighed it. I then picked up the bag from the table where it was placed, pressed a pedal to heat-seal the bag, and passed it to another worker who marked its “best before” date. I then repeated the process thousands of times for an entire week.

With the earplugs in, the factory quickly became a very solitary place, despite our constant teamwork, and my mind wandered easily. I quickly learned that developing a rhythm would be necessary if I was to keep pace with Sosefina, who weighed the bags before placing them onto the small metal table. Fortunately, “the Bosch” – a large, noisy machine that performed a mechanical process similar to our manual one – provided me with a suitable tempo.

One day I arrived to find that our team had been moved upstairs, to a warm, airy room full of tanks. The process was the same, but the sound was not. Without the Bosch’s regular clanking to keep time, I had to improvise lest the bags pile up. “Steve Gutenburg, Steve Gutenburg,” I chanted in my head, and this seemed to do the trick. While the Mighty Ducks star’s name had just the right number of syllables to pick up, turn, seal and pass on the packets, it clearly had a greater significance. I was, I realised, not like Steve but rather like Johannes Gutenburg, with my crude version of a printing press.

The message I left on the little coffee bags read, “I am vacuum-packed and delicious.” Like most things that are printed, this was totally fictitious. The bags were half full of air, and Greggs’ coffee tastes disgusting. Its only buyers, I suspect, are those possessing a faint, vestigial chauvinism that tells them to “buy Kiwi made.” Such a mantra appeared all the more ironic after I entered the break-room one morning to find the factory’s engineers peering into a little plastic bag in which they had trapped a cricket. It had apparently hitched a ride from Vietnam, where the factory’s coffee beans are grown. They had named him George (after the royal baby) and were urging him to “eat some yoghurt, it’s right in front of you,” as I returned to the factory floor.

Our team of five (two scoopers, one weigher, one sealer and one boxer) was suddenly reduced to four as our production line became more automated. A machine now poured coffee powder from a long pipe, eliminating the clouds of dust that manual scooping created and, to my delight, the coffee-clogged nostrils I had consequently endured. However, the stampy satisfaction of sealing bags was therefore replaced by a new role: opening the packets by pushing them headfirst onto a metallic knob. As the “shaft-master,” my field of vision became even more solipsistic. Staring at the stainless steel appendage on the workbench, I watched my surgeon-like reflection disappear several times per minute under the upended bags. This, I imagined, resembled the final vista of those who die when their organs are harvested.

Distressing though that thought was, my simple task was soon made more stressful as it came under the gaze of the efficiency-seekers. Glenys, the big boss of the factory, borrowed my wristwatch one Wednesday. Counting the number of packets we produced per minute, she pointed in my direction and told her off-sider Diane, “we’ll get rid of that one after a few days.” By Friday, my brief sojourn at Greggs’ had come to an end, and Select’s Amanda sent me a smiley face-infested text message asking if I’d “like to be on call tomorrow” for a variety of one-off jobs.

Being on call has a purgatorial quality to it. Unable to plan for the day (or the night) ahead, I floated about, performing mundane household tasks as I waited for the phone to ring. It seldom did. When I was finally called up, however, I was in for a treat. A conference for GPs was to be held, and able hands were needed to erect the accompanying stalls. Heavy though the work was, constructing the fake little market in the Edgar Centre afforded me a glimpse at some of the strangest advertisements I’ve ever seen. Somewhere, an acid-addled “Creative” had been paid to produce the following advertisements. Compared to the factory’s dust and drudgery, this was the closest I got to a cultural experience during my months of prole life.

Early one Sunday morning, I was called in to work at Mainland Poultry’s Zeagold plant in Waikouaiti. Donning, once again, white work-wear and a hairnet, I was placed in front of a conveyor belt by Sheryl, my affable supervisor. The belt began to move, and from behind a steel wall came hundreds of eggs. “The crackers go in this one,” Sheryl instructed, placing a fractured shell into a cardboard tray. “The commercials go here,” she said, popping a poop-smeared egg into another, “and the shitties go into this one.” There have never been eggs as unappetising as those in the third tray. I later learned that they were made into a household brand of pavlovas. The slightly dirty eggs went to commercial kitchens, and “the crackers” were broken into buckets and sent to McDonald’s and Cookie Time to be made into scrambled eggs and biscuits respectively.

A quarter of a million eggs passed across that belt daily, although they soon began to resemble stones. To break out of this lucid hallucination, I attempted to strike up conversation with my colleagues. Shona, a self-described Critic-lover (“it’s got heaps of swear words”), told me tales of race-fights in the Australian abattoirs where she used to work. “There was this car-park,” she enthused, “and all the Aussies would gang up on the Maoris and the Filipinos.” Shona hid from the fisticuffs, in both the chiller and her growing alcohol dependency, which resulted in her eventual sacking.

Other belt partners included Wiremu, a moko’d nose flautist who provided the soundtrack to Vincent Ward’s later works, and Huia, who became frustrated with another machinist’s failure to crack the “crackers.” “Look at all these eggs, son,” she exclaimed, “look at these fucking mountains!” As my workmates’ names suggest, Sir Tipene O’Regan’s prediction that “in 20 years, New Zealand will have a brown proletariat” seems to be coming to early fruition.

My passable performance led me to be promoted to the position of “pallet wrapper” in the storeroom. This job was significantly more challenging, consisting of processing order slips and wrapping boxes of cartons of eggs in plastic film using the fantastic “spinny” machine. It wove a wonderful web of glad-wrap around the eggs, while I filled out order slips and placed “FRAGILE” stickers on the outside. Charlie, a recession-ruined former property investor, had warned me of the job’s pace while he graded eggs. “I only lasted a day there,” he said glumly. “They said I was slowing them down.”

Certainly, keeping pace with the entire factory’s output was challenging. The upside of the job was finding out where all of these eggs were going. Unlike the workers themselves, many of whom were doomed to eke out an existence in the social prison that is Waikouaiti, the eggs were shipped to several exotic locations, including Singapore, Hong Kong and Tahiti. “I fucking hate this place,” one worker confided in me, and I suggested that she hide in the middle of an export pallet to await her shipment to some foreign shore.

I sometimes wondered whether the workers had, like me, found themselves in the job by fate, or had made some God-awful series of choices that had trapped them there. Answers were consistently tenuous. Harry had broken his foot while enjoying a post-town feed of fish and chips and lost his temporary job at the port as a consequence. Ted, who had escaped the Nazis as a child, was getting back to work after a head injury. Jordan was saving money and even hoped to buy my second hand scooter when I left, but a sudden bill broke the deal for him. In all manner of ways, it seemed, we were cursed to work our whole lives through.

It would be easy to read this story and remind oneself how lucky one is, or to chuckle at the absurd, mundane and miserable lives of others. However, I challenge the reader to imagine themselves in such an uncomfortable position and wonder if this is the “God’s own country” their ancestors sought to build.